Hola readers!

Thank you to the 36 odd subscribers who signed up to receive my newsletter!

The brand in spotlight this week is “Zara”, a brand my sister has recently grown fond of. While she was busy shopping in the store, I started wondering how the company is able to put out so many designs so regularly!

I was surprised when I visited the same Zara store in Bengaluru after a month and saw that the entire stock was replenished!

PS: Feedback from the readers is most welcome and I would also like to know what you’d want to read about in the upcoming newsletters!

Here's to hoping that the newsletter adds value to the you, the reader.

Let’s get to the blackboard and look at some of the terminologies used in the newsletter today, shall we? #NishTeaches

What Is Fast Fashion (FF)?

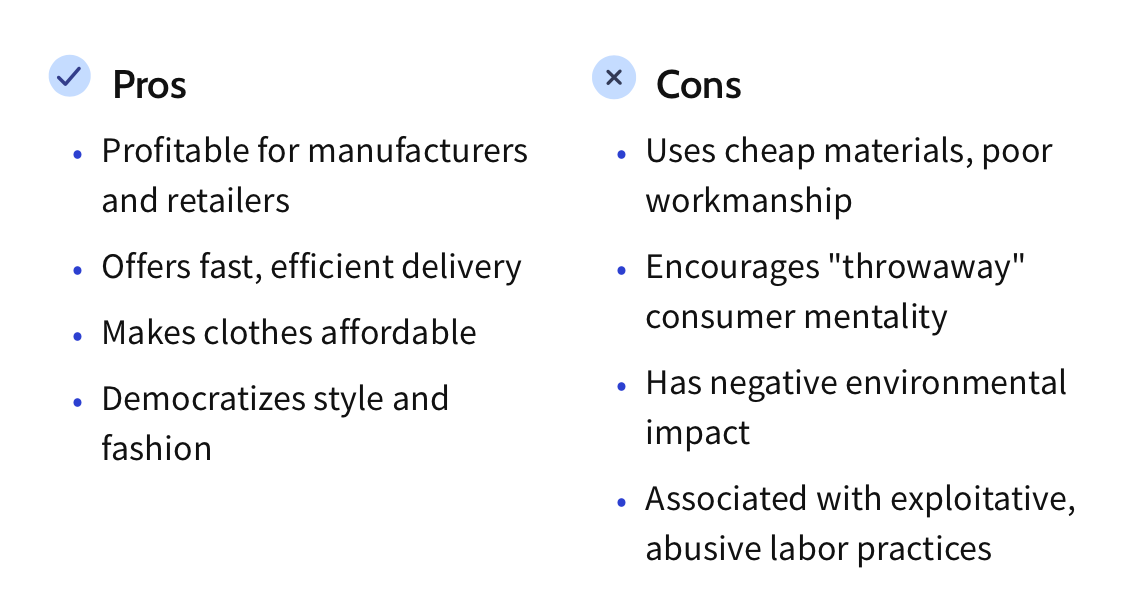

Fast fashion is the term used to describe clothing designs that move quickly from the catwalk to stores to take advantage of trends. The collections are often based on styles presented at Fashion Week runway shows or worn by celebrities.

Does that make fast fashion expensive?

It’s in fact the opposite: consumers are able to purchase the new look or the next big thing at an affordable price. Fast fashion became common because of cheaper, speedier manufacturing and shipping methods, an increase in consumers' appetite for up-to-the-minute styles, and the increase in consumer purchasing power—especially among young people—to indulge these instant-gratification desires.

How is it changing fashion trends?

FF is challenging the established clothing labels' tradition of introducing new collections and lines on an orderly, seasonal basis. In fact, it's not uncommon for fast-fashion retailers to introduce new products multiple times in one week to stay on trend.

Startling facts about the fashion industry

Clothing production is the third biggest manufacturing industry in the world.

The fashion industry is responsible for 8% of global carbon emissions.

Open-loop fashion production cycles are responsible for both land and water pollution.

10 to 20% of harmful pesticide use is caused by the fashion industry.

Less than 11% of brands are beginning recycling strategies.

60% of fast fashion items end up in a landfill.

20% of industrial water pollution is caused by solvents and dyes used in garment manufacturing.

Fast fashion is second - only to oil - as the world’s largest polluter.

About Zara

Zara was founded by Amancio Ortega (featured as #2 richest person in the world in the past years) in 1975 and is a flagship clothing chain store that is part of Inditex group, the world's largest apparel retailer. Amancio Ortega opened the first Zara store in 1975 in central A Coruña, Galicia, Spain where the company is still based. Ortega initially named the store Zorba after the classic 1964 film Zorba the Greek, but after learning there was a bar with the same name two blocks away, the letters were remolded for the sign to say "Zara".

Zara initially sold low-priced lookalike products of popular, higher-end clothing lines. Eventually, during the 1980s, Ortega changed the design, manufacturing, and distribution process to reduce lead times and react to new trends in a quicker way, which he called "instant fashions".

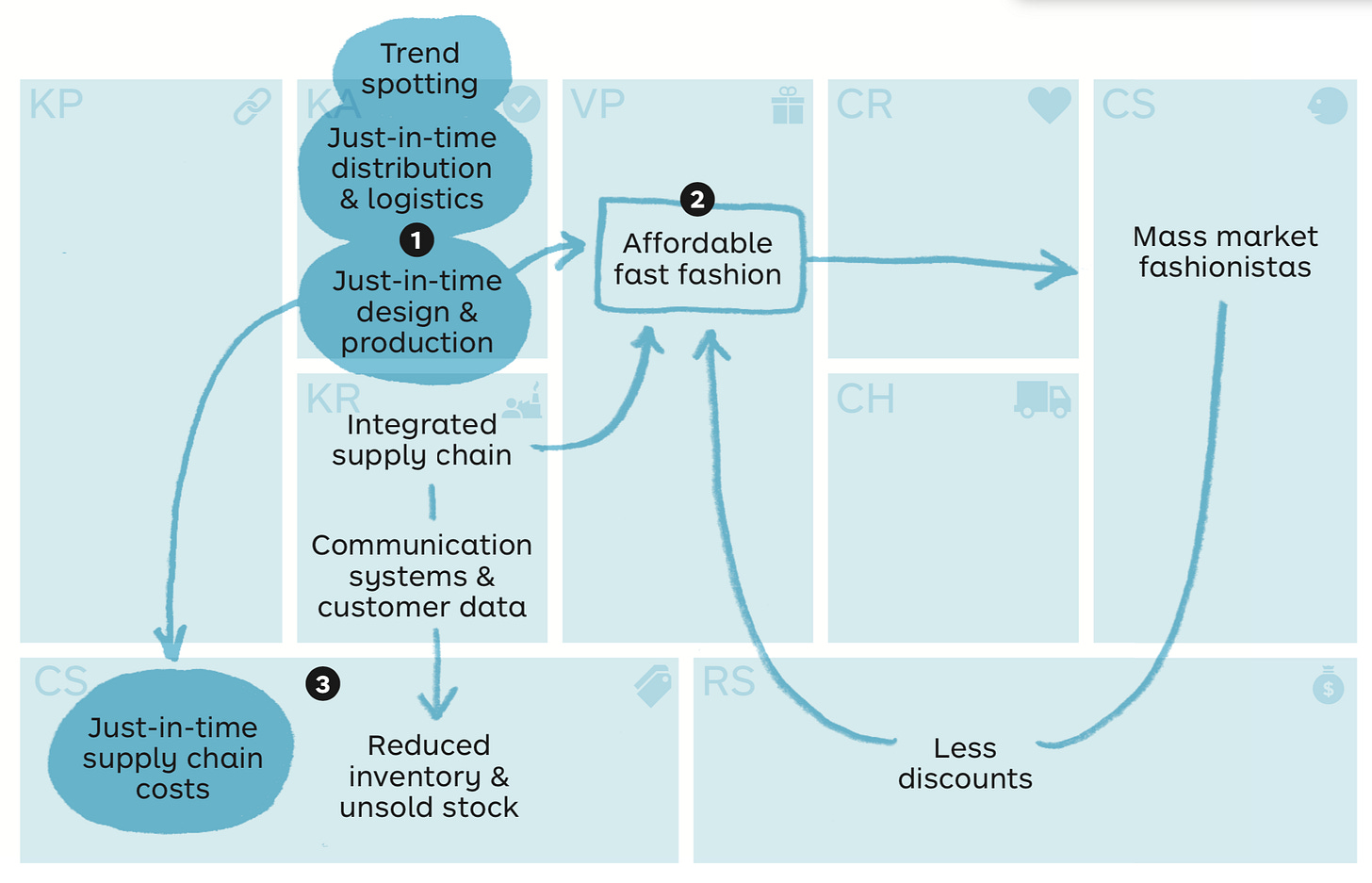

Zara’s business Model

What makes Zara stand out?

The company’s value proposition lies in both design and speed – industry analysts argue that no other company reacts to fashion trends and turns trends into actual shipments to stores as quickly as Zara. The whole production cycle – from initial design to point of sale – takes Zara around two weeks while competitors spend six months in average to introduce new product to the market.

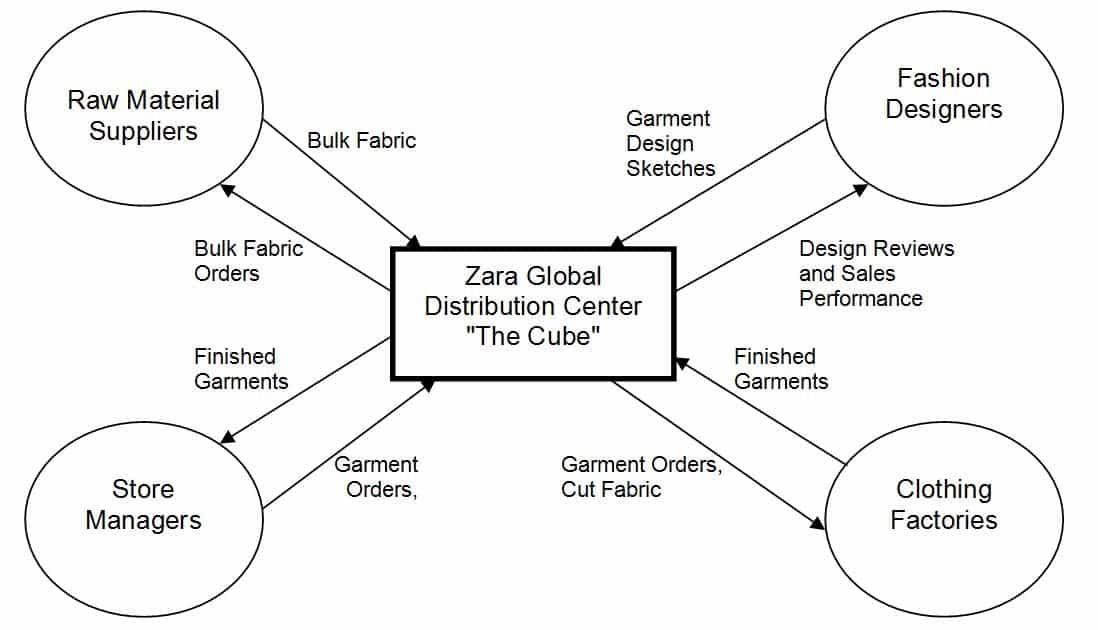

The company created innovative manufacturing process allowing quickly responding and selling clothes to its stores. Zara controls key components of its supply chain: designing, manufacturing, distribution, and retailing.

Designing

A group of designers are divided into teams to come up with new designs to pitch to the supervisors. Taking insights from the data received in the form of feedback from customers and in the form of initial analysis done by the computer systems, the designers roll out a flurry of designs. The teams are shuffled every few months; employees with lower scores after several team rotations are let gone and those with higher scores get promoted to supervisors.

Manufacturing

Zara uses in-house manufacturing to manage the never ending demands of the customers and also to facilitate the release of the newest and trendiest designs into the market. Instead of following season specific changes, it produces 50-60% of clothes in the start of the season.

Distribution

Zara’s highly responsive, vertically integrated supply chain enables the export of garments 24 hours, 365 days of the year, resulting in the shipping of new products to stores twice a week. After products are designed, they take around 10 to 15 days to reach the stores. All clothing items are processed through the distribution center in Spain, where new items are inspected, sorted, tagged, and loaded into trucks. In most cases, clothing items are delivered to stores within 48 hours.

This vertical integration allows Zara to retain control over areas like dyeing and processing and have fabric-processing capacity available on-demand to provide the correct fabrics for new styles according to customer preferences. It also eliminates the need for warehouses and helps reduce the impact of demand fluctuations.

What distinguishes Zara’s supply chain?

Daily collection of customer insights: Trend information flows daily into a database at head office, which is used by designers to create new lines and modify existing ones.

Standardisation of product information: Zara warehouses have standardised product information with common definitions, allowing quick and accurate preparation of designs with clear manufacturing instructions.

Product information and inventory management: By effectively managing thousands of fabric, trim and design specifications and their physical inventory, Zara is capable of designing a garment with available stock of required raw materials.

Procurement strategy: Around two-thirds of fabrics are un-dyed and are purchased before designs are finalised so as to obtain savings through demand aggregation.

Manufacturing approach: Zara uses a “make and buy” approach – it produces the more fashionable and riskier items (which need testing and piloting) in Spain, and outsources production of more standard designs with more predictable demand to Morocco, Turkey and Asia to reduce production cost.

The fast fashion industry on the outside looks exciting and profitable but is there any downside to the environment due to the continued demand for new designs and the materials used by brands to manufacture clothes?

Is fast fashion sustainable?

Whenever we talk about fashion, its association with sustainability is inevitable to creep up in the conversation and how can we not talk about the same here?

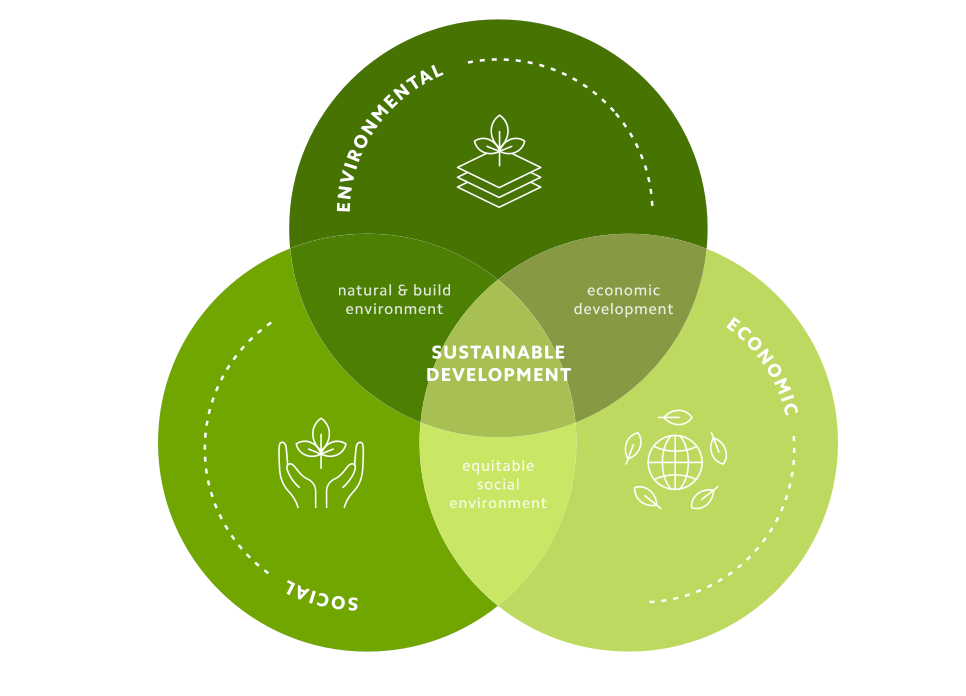

Let’s begin with defining sustainability.

In business, sustainability refers to doing business without negatively impacting the environment, community or society as a whole.

The three pillars of sustainability are:

Environmental Pillar

Initiatives that reduce the carbon footprint of the business throughout the value chain.Social Pillar

Initiatives promoting the wellbeing, health and safety of communities, customers and employees.Economic Pillar

Initiatives that ensure businesses can thrive while making these long-term positive impacts.

What are the steps that Zara has taken towards becoming sustainable after the scrutiny from the world on fast fashion brands?

Working towards sustainability

Under the slogan ‘Working towards sustainability’, Zara highlights in bold letters some of its most significant actions, such as politically fuelled programs, integrating social and environmental sustainability and the health and safety of its products. Garments labelled with ‘Join Life’ are produced using processes and raw materials that help reduce environmental impact. The company is now aiming that 50 percent of its products will meet the ‘Join Life’ standard by 2022.

Its boxes, bags, hangers and alarms are reused and recycled at the end of their useful life. Bags given to customers are already made from 100 percent recycled paper, and by 2023 they will eliminate all single-use plastics given to customers.

Currently, its shops have been renovated to prioritise efficient consumption of energy and water and zara.com’s servers use renewable energy. The goal is that by 2022, 100 percent of the energy in its headquarters, logistics centres and own shops will come exclusively from renewable sources.

Well-informed garments

The garments in the ‘Join Life’ collection are accompanied by a tag, specifying the material used in its manufacturing, the care required to sustain the quality of the garment and its origin.

Its use of European linen and recycled polyester and its manufacturing in Morocco and Tunisia already show Zara’s progress in fulfilling its sustainable mission

Watch the below video to gain more insights on how the part group of Zara, Inditex, is envisioning sustainability for its subsidiary brands - Zara - Join Life

I’ll want to leave the readers with a question to ponder upon. Is it time that we as shoppers/buyers proactively be on the lookout for brands that are sustainable? Or should we continue to put forth our “wants” before the future of this planet?

Love,

Nishant